Pervaporation & Vapor Permeation

KL-AIR for Pervaporation & Vapor Permeation

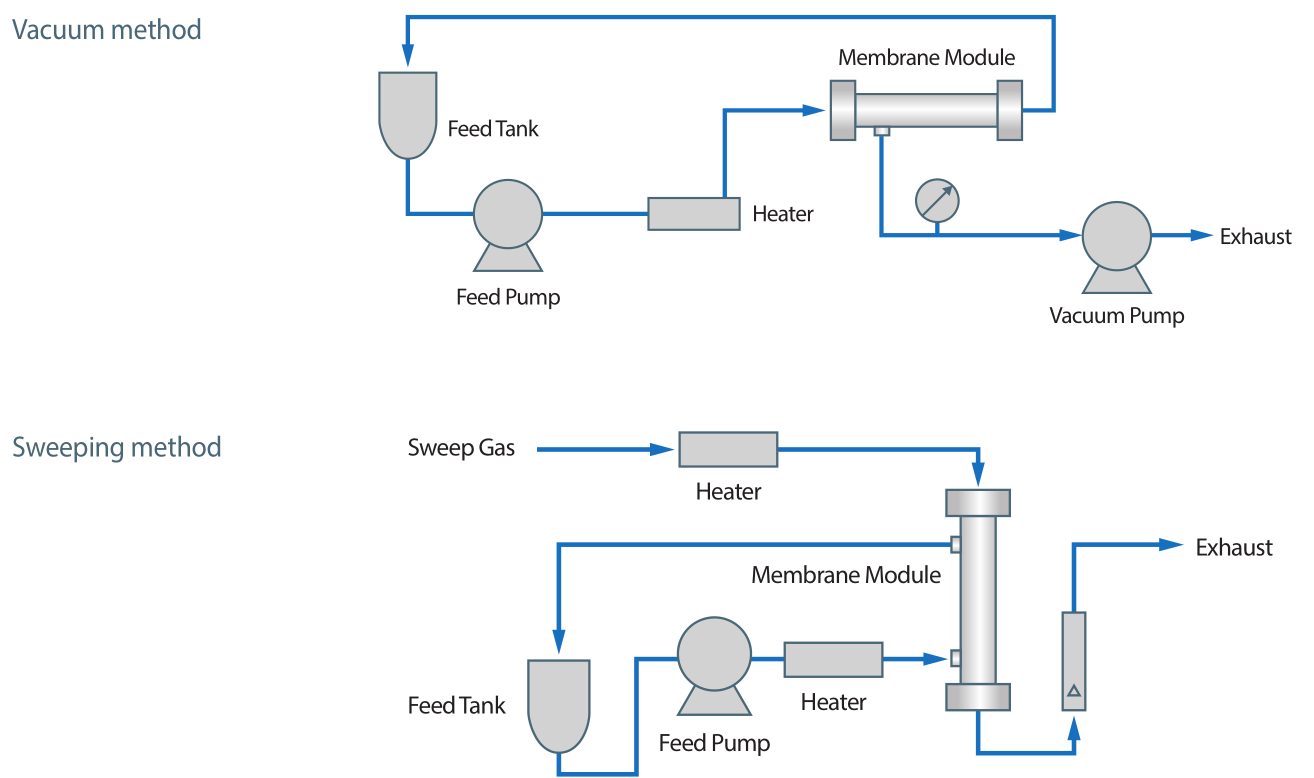

Schematic Diagram

Pervaporation is derived from the two steps of the process, permeation through the non-porous membrane by the permeate, then its

evaporation into the vapor phase which is condensed into liquid phase. Membrane acts as a selective barrier between the two phases, the

liquid-phase feed and the vapor-phase permeate. It allows the desired component of the liquid feed to transfer through it by vaporization.

Pervaporation technology could be applied to the separation of alcohol/water mixture, organic compound/water mixture and vapor

permeation process.

Key Applications

|

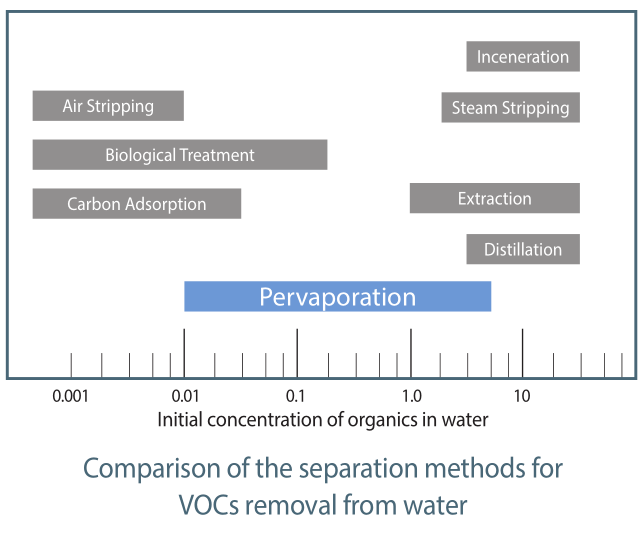

● Dehydration of water/organic liquid mixture ● Removal of VOCs from water/organic liquid mixture ● Separation of organic/organic liquid mixture |

● Monomer recovery from polymerization process ● Oil mist collect from oil storage tank |

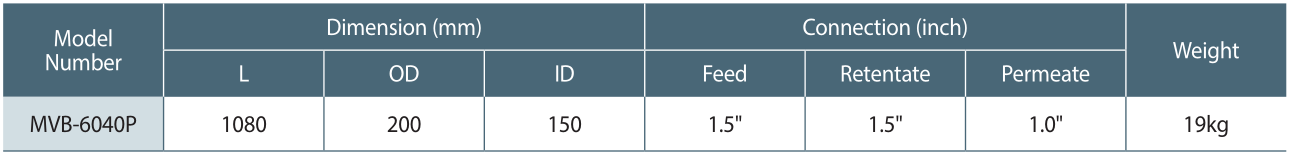

KL-AIR Product Specifications

Why Membrane Pervaporation?

● Low cost separation without chemical additives ● Effective separation even with small gap of boiling points of mixture. ● Low energy consumption system for vapor permeation ● Compact size facility with module designing ● Easy and quick start-up system ● High purity permeate attainable |

|

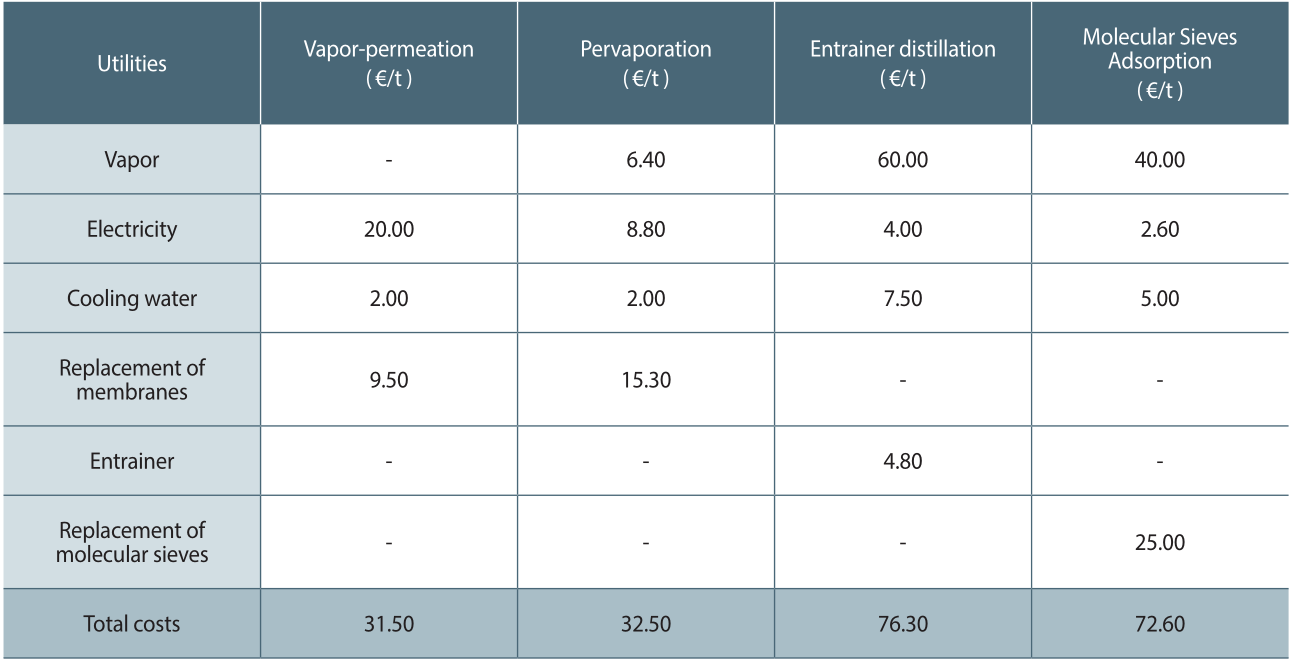

Comparison of dehydration costs of ethanol from 94 vol% to 99.9 vol% by different techniques