What are the requirements for air dryers for medical compressed air?

With the deep reform of the national medical system and the continuous improvement of the life support system of the medical industry, medical compressed air has also become an important part of the modern medical system and a life support system. Its importance has been highly valued. GB50751-2012 "Technical Specifications for Medical Gas Engineering" hereinafter referred to as the "Specifications" has detailed regulations on the quality of compressed air.

For the design and application of medical compressed air systems, not each air compression equipment manufacturer is familiar with it. Depending on the design drawings of major hospitals in the medical industry to choose to match, it is inevitable there are many matching phenomena. This article focuses on the characteristics of the medical compressed air system and the requirements of the "Specifications" in which the adsorption air dryer tower is introduced.

Select the role of adsorption air dryer tower

For air compressed air system, air dryers generally have two options: refrigerated air dryers and adsorption air dryers. Refrigerated air dryers are not very suitable for medical compressed air systems due to their design features listed below.

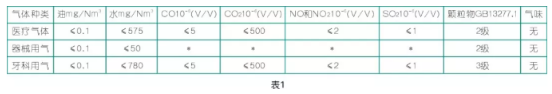

One is that the pressure dew point can only reach 2-7℃; the other is that the operation of the air-cooled air dryer requires environmental temperature. When the ambient temperature is high in summer, the output air dew point is not reliable; At 30%, the efficiency of the air-water separator of the refrigerated air dryer is very low, causing the condensed droplets to reach the downstream system with the air, causing a downstream dew point alarm, especially when the air volume is greatly reduced at night, the "Specification" has a clear water content Regulations (Table 1).

Since a low dew point is necessary for medical compressed air, the reason is that it can inhibit microorganisms. To meet the 50mgNm3 medical device air moisture content requirement, the pressure dew point of the air must reach -27 ° C. The European Pharmacopoeia also clearly display that at a pressure dew point of -27 ° C, the growth of microorganisms will be obviously inhibited.

The second reason is to protect the activated carbon filter. The activated carbon degreasing and deodorizing filter in the compressed air system requires the compressed air to have a dryness of -40C pressure dew point, otherwise the humid compressed air will reduce the life of the activated carbon;

The reason three is to protect the CO catalytic filter. The currently designed CO catalytic converter can reduce the concentration of 65ppm to 5ppm. However, experiments show that if the CO catalytic filter has insufficient dew point (above -40 ° C), it can only reduce the CO concentration of 15ppm to 5pm. From the above three points, the medical system should choose an adsorption air dryer with a pressure dew point of -40 ° C.

Selection requirements of adsorption air dryer

Selecting an adsorption air dryer to achieve reliable dew point and function requires consideration of the following important factors:

Flow rate

Adsorption air dryer flow in accordance with the actual average maximum consumption of air to choose, and it can also be selected according to the air supply of the air compressor. What needs to be clarified here is that in a 7 bar pressure system, the adsorption air dryer generally consumes 15% of the flow for the regeneration of the desiccant. These losses should be fully considered when designing the system.

Minimum working pressure

When the actual air consumption is greater than the air supply capacity of the air compressor, the pressure of the compressed air system will decrease, which will cause the adsorption dryer to exceed the load and the output dew point is unreliable. There are two reasons; One is lower pressure, which increases the volume flow, and compressed air creates more "moisture"--water vapor. Two volume flow rate, resulting in compressed air in the air dryer too fast. water vapor is not fully dry, thus affecting the drying effect Prevent the air dryer overload, you can set the flow control.

Air inlet temperature

The moisture content of compressed air is closely related to the inlet temperature. The standard inlet temperature of adsorption dryer is 35℃. If the inlet temperature becomes 50℃, the compressed air entering the air dryer will carry more than twice as much water vapor as the air dryer can handle. The adsorption capacity will decrease, resulting in the outfall dew point below-40℃.

The adsorbent capacity varies with temperature. The adsorption capacity of adsorbent decreases with the increase of temperature. For alumina, the adsorption capacity decreases greatly when the temperature reaches 50℃. So generally speaking, the standard intake temperature of adsorption dryer is 35℃.

Energy saving

Small pressure loss:(1)modular design, even distribution of airflow, even drying: 2)filing method of snowstorm to avoid air shock to cause desiccating agent wear, powder will further increase resistance, and lead to dust "pollution" of subsequent equipment: 3) built-in nlet and outlet filters to minimize resistance loss caused by external filters and pipelines.

When use dew point control rather than standard

Due to the inthuence of inlet temperature and pressure, the timing controller often chooses air dryer with a larger treatment capacity to ensure reliable dew point in the selection process, which causes that in most cases, the actual flow rate cannot reach the rated treatment capacity, and the drying cylinder cannot be fully utilized, so it will switch to regeneration, and the regeneration will continue.

In fact, from the perspective of the operating cost of the whole life cycle of the equipment, the investment in the early stage is only a very small part of it and the much more investment is the operating cost of the equipment. With 10Nm³/min system, if the systems average gas consumption is only 50%(and the systems capacity utilization is actually less than 30% in the evening and most of the time). so the energy savings from switching between air inlet temperature and dew point can be at least 60%. The dew point control mode is adopted, Under the condition of low low rate, the drying cylinder will continue to work until the dew point of the gas is close to the control point and then switch over. After the regeneration of the recycled gas, it will stop consuming and then recharging and stay in the waiting state, during which the regeneration consumption will be greatly save.

If the modular adsorption dryer can be designed, compared to the traditional twin tower dryer, has a smaller volume, lighter weight, more easy to install and transport, almost no need for special moving tools. It is more suitable for the quiet and reliable life environment in the medical industry.

Can reduce equipment maintenance task. Can be on-site loading desiccant, will not cause desiccant rapid powder, blocking the silencer, resulting in energy waste, and even cause downstream air polution and equipment congestion This desiccant is beneficial for the use of vital system gas in the medical industry.

In terms of control and alarm air dryer system. with dew point control and alarm mode remote control functions, can be linked to the hospital smart energy system, to achieve the control and management without resistance. The control function requirements are as follows: when the pressure dew point of the air dryer is better than-42℃, the air dryer can supply air without affecting the system flow and pressure, and the system will prompt the alarm and upload the data to the intelligent management system. When the pressure dew point is higher than -40℃. the machine is in normal mode to ensure that the dew point reaches -40℃. Under normal circumstances, if the dewpoint of the air dryer does not reach -30℃, an alarm signal will flash on the panel and activate the remote alarm system, indicating the need for maintenance.

To sum up, in the face of higher and higher requirements for compressed air system air quality in the medical industry system, it is necessary to ensure that the compressed air can always obtain reliable dew point and stable system operation. At the same time, the operation of high efficiency, energy saving and low carbon environmental protection also takes more and more into consideration the wisdom of design and management. so the overall cost should be considered from the perspective of equrpment selection.